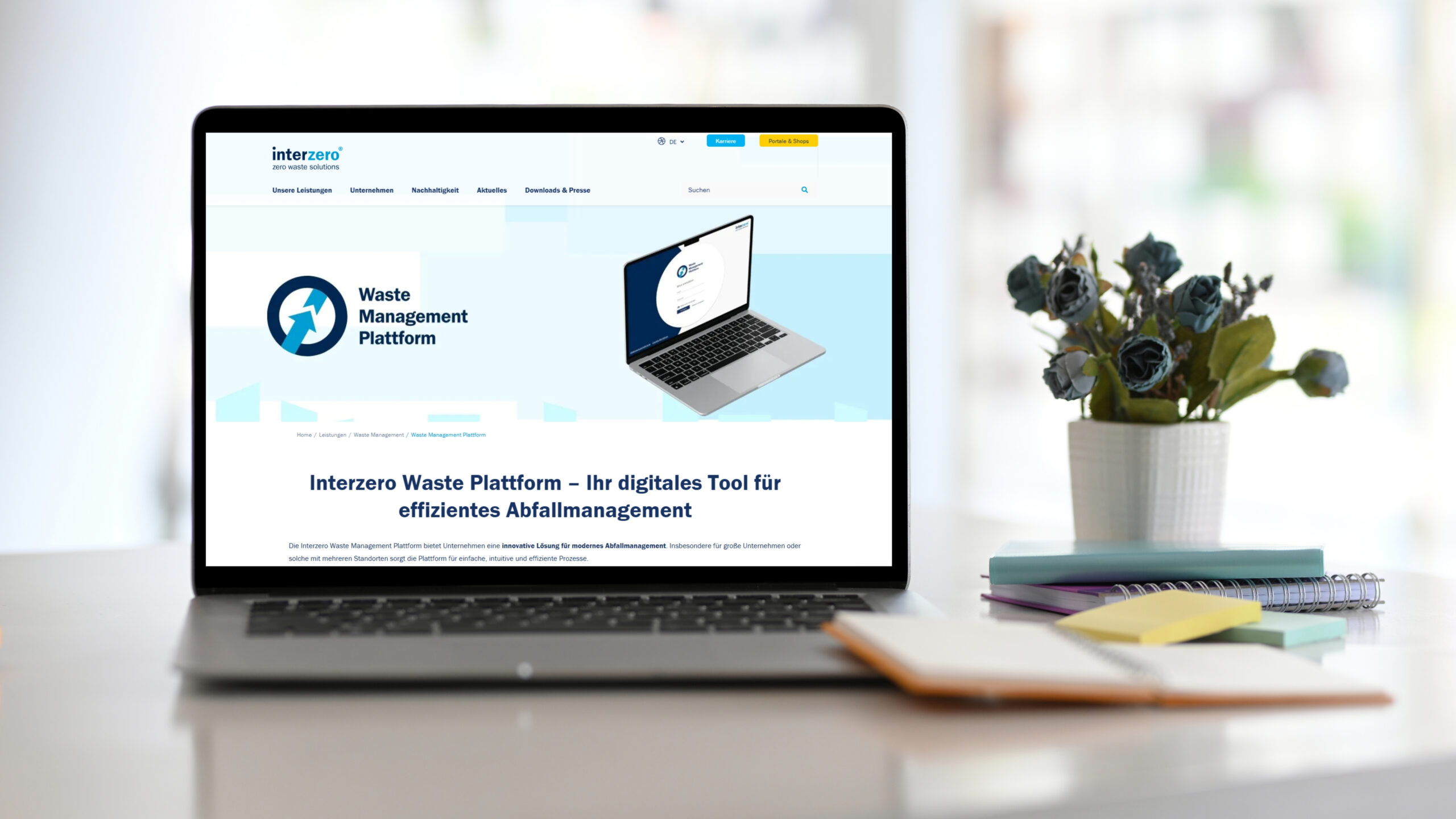

Transparency, efficiency, savings – how our digital platform measurably relieves the burden on companies

Scattered information, multiple contacts, unnecessary transport, and a lack of overview: In many companies, waste management has evolved over time – but is inefficient. This is precisely where the Interzero Waste Management Platform comes in. It creates centralized transparency, reduces coordination effort, and makes savings potential visible and usable.

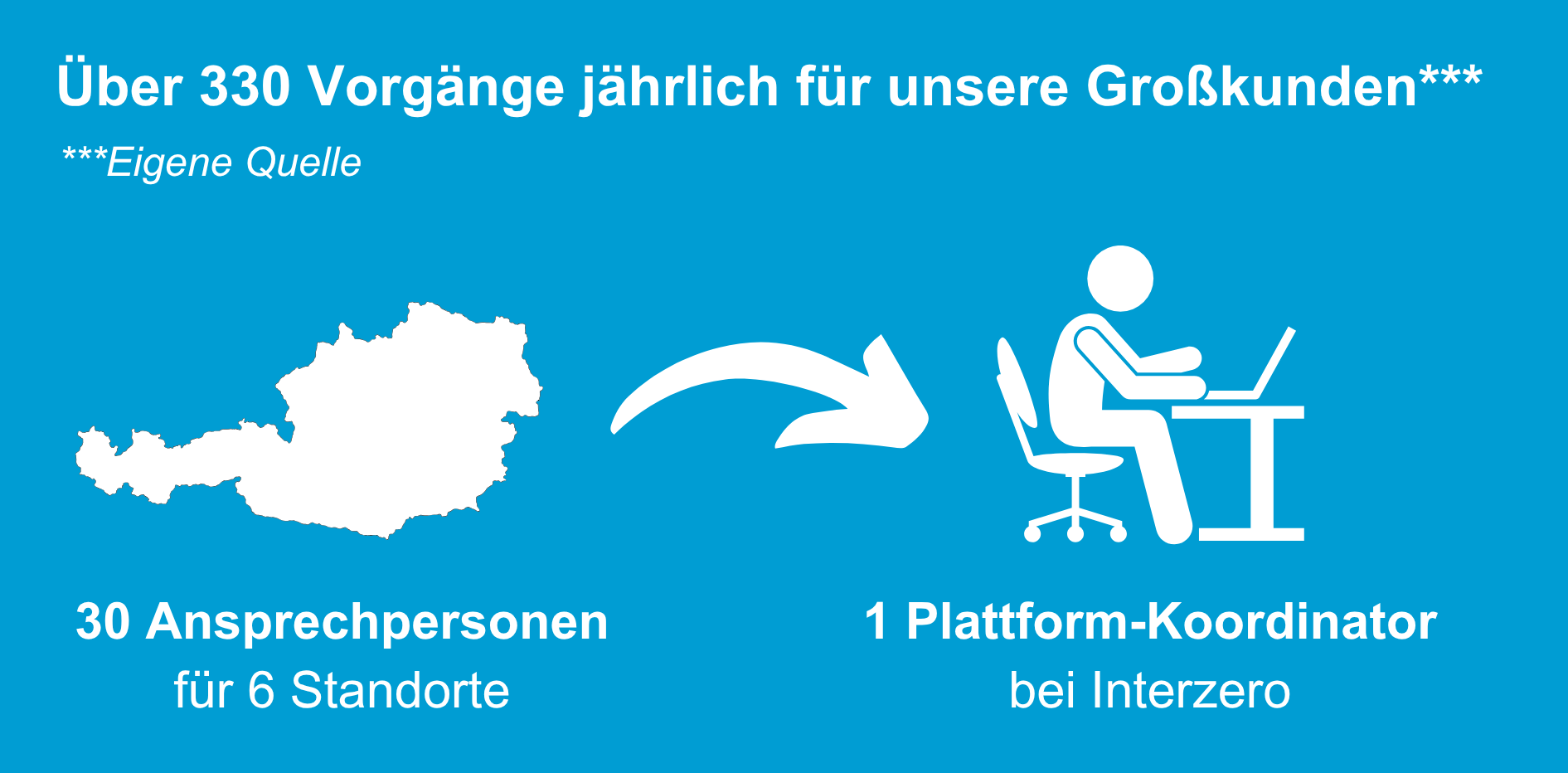

A concrete example shows what this looks like in practice:

For one of our major customers with six locations in Austria, we coordinate 332 pickups annually via our platform. In the past, this meant communicating with around 30 contacts, numerous emails, and a lot of coordination. Today, everything is handled centrally, efficiently, and transparently via our digital solution.

The result:

- Over 330 pickups centrally documented and controlled

- Communication via a single contact person at Interzero (“one face to the customer”)

- Projected time savings: up to 10 full working days per year*

(*Basis: 15 minutes time saving per pickup = approx. 83 hours annually)

And that’s just the beginning: In addition to saving time, companies also save money with the Interzero Waste Management Platform – through more efficient route planning, better material flow analysis, and sound decision-making bases for disposal and recycling concepts.

Future included:

We are continuously working on additional modules – for example, for the integration of sustainability metrics (e.g., CO₂ savings), automated reporting, and AI-based recommendations. This makes the platform an indispensable management tool for modern environmental responsibility.

Learn more about the Interzero Waste Management Platform:

Please feel free to contact your personal contact person directly - arrange a short appointment, clarify any open questions or request a trial version.

Would you like to test the Waste Management Platform? Do you have questions?

contact form

Latest News

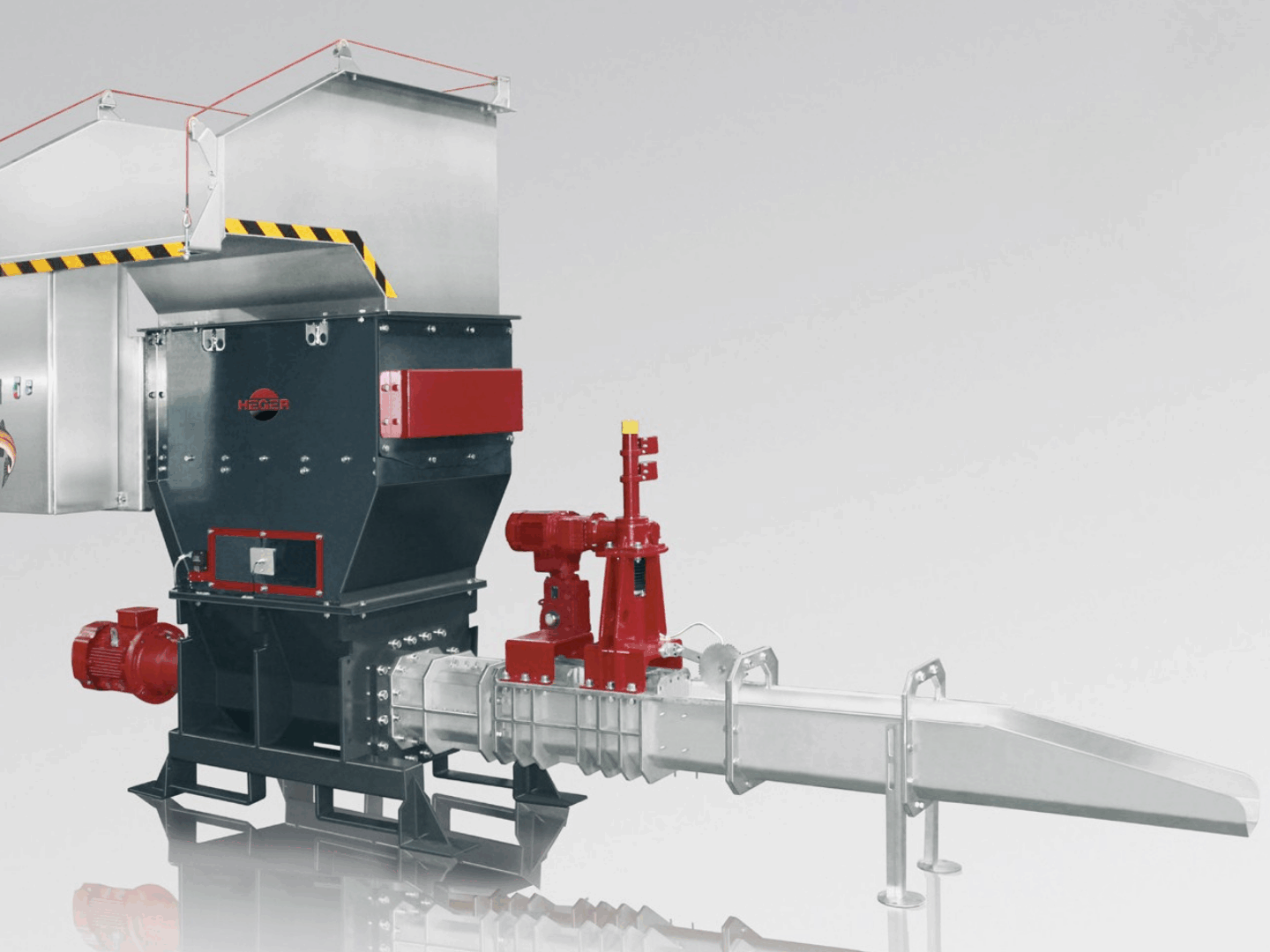

Compact efficiently:

Our new machine solution for EPS

Summer webinars:

Knowledge that works

Whitepaper Circular Economy:

Current market insights & trends

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Whitepaper Circular Economy - current market insights and trends

Sustainability is not a passing trend; it has long been a part of corporate reality. More and more companies are adopting circular business models – not just out of conviction, but because it pays off economically. Our new white paper offers in-depth insights into current developments and shows where Europe really stands in terms of the circular economy.

Numbers that encourage rethinking – and become inspiration

Our market study among decision-makers from six European countries shows:

- 60.4% of companies already have a strategy for sustainable development.

- 75% have defined environmental goals – many of which have already been achieved.

- 72.9% rely on more sustainable processes in design and production.

Only 7.8% of the companies surveyed are not currently planning to switch to circular models – a clear signal: the transformation is in full swing.

But how exactly can this transformation be achieved in everyday business operations? What measures can be implemented quickly? And how large are the budgets that companies allocate for sustainable development?

Our current white paper provides answers

The Interzero white paper “Companies and the Circular Economy: A Detailed Analysis” offers:

- current sustainability trends and their impact on the market,

- Practical examples and benchmarks for the implementation of circular strategies,

- Insights into budget structures and ESG reporting,

- an assessment of the prevalence of support tools and partnerships.

A valuable compass for all those who want to not only think about sustainable measures but actively implement them.

Please fill out the form to access the white paper results:

Do you have questions about the white paper? Do you need help developing a sustainability strategy for your company?

Write to us at the email address below!

Latest News

Compact efficiently:

Our new machine solution for EPS

Summer webinars:

Knowledge that works

Digital waste management:

Transparent, efficient & economical

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Textile recycling in transition: Why companies should act now

A global problem – with growing pressure to act

The global textile industry faces massive challenges: Over 92 million tons of textile waste are generated annually – yet less than 1% of this is recycled into new textiles. This linear model is neither ecologically nor economically viable.

With Extended Producer Responsibility (EPR) for textiles, the industry is at a turning point. In the future, companies will be held more accountable – from the design to the end of their products’ lives .

Situation in Austria: The cycle is stalling

There is also an urgent need for action in Austria: More than 220,000 tons of textile waste are generated annually. Only around 26% of this is collected separately , and less than 2% is recycled.

A large portion ends up incinerated or landfilled—a waste of valuable raw materials. Even damaged textiles—with stains or tears—could serve as the basis for new textiles , provided suitable collection, sorting, and recycling structures are in place.

Separate collection of used textiles has been mandatory throughout the EU since January 1, 2025. Regulatory pressure is increasing – and with it, the responsibility for companies.

Regulatory change: EPR & PPWR – more responsibility for companies

The EU Packaging Regulation (PPWR) also entered into force at the beginning of 2025. Together with the EPR, these regulations mark a paradigm shift: companies that place products and packaging on the market will in future be responsible for their entire life cycle .

In Austria, the EPR currently applies to packaging, waste electrical and electronic equipment, and batteries. However , textiles are also increasingly becoming a focus of legislation . Countries such as France, Sweden, and the Netherlands have already introduced corresponding systems; Austria is working on national implementation .

For affected companies, this means that anyone who places textiles or textile components into circulation will also have to assume financial responsibility in the future.

Future textile cycle: What is necessary – and what is already being created

A functioning textile cycle requires more than separate collection. The challenges are diverse:

- Variety of materials , such as blended fabrics made of cotton and polyester

- Chemical residues and low quality in fast fashion

- High logistical effort in collection and sorting

- Lack of sales markets for high-quality recyclates

The goal: a functioning, circular textile economy that conserves resources, reduces waste and promotes long-lasting products.

Interzero: Clear position & active implementation

“The issue of fast fashion and its negative impact on our planet concerns us all!

— Thomas Glatz, Managing Director of Interzero Austria

Interzero positions itself clearly:

“The transition to a circular textile economy is one of the biggest transformations the industry has ever faced.”

Our self-image:

We are not just consultants – we are implementers.

Your advantage as an Interzero partner

Even if the legal pressure doesn’t yet directly affect all industries, the development is clearly marked . Interzero supports you with concrete solutions to ensure timely and future-proof action:

- Regulatory security through strategic advice and support

- Systemic solutions along the entire take-back and recycling chain

- Sustainable competitiveness through resource-saving circular models

Think about the future together. Act sustainably.

- Let us convince you of our expertise in collection, sorting and recycling .

- Interzero Austria develops individual take-back systems with which you can close your textile cycles .

- Now is the right time to take action. Talk to us – we will accompany you.

Latest News

Focus discussion on sustainable packaging solutions:

Cooperation with Leitbetriebe Austria

Machine service at Interzero:

Well looked after all round

Interzero Webinars & Events:

Stay up to date!

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

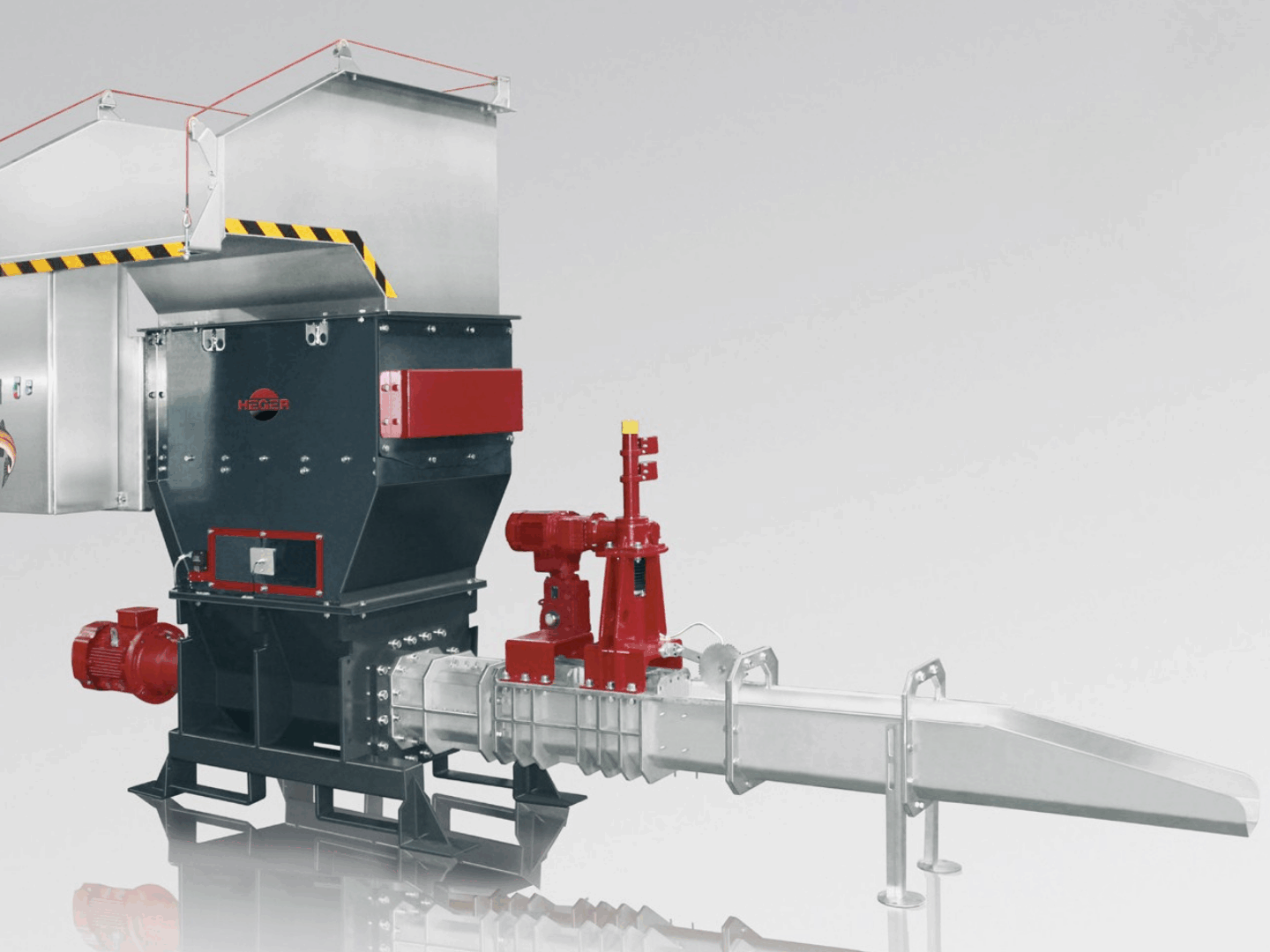

Machine service at Interzero: Well-cared for all around – for a long service life of your machine

Interzero stands for modern compaction technology that not only saves space but also optimizes processes.

Waste and recyclable materials take up valuable space and cause avoidable costs. With a wide range of balers, container presses, and specialized solutions, Interzero offers you the right technology for almost every industry – and we take care of more than just delivery.

Our in-house, manufacturer-certified service team ensures smooth operations from day one: We professionally install your machine, commission it, and train your employees directly on-site – so you can get started safely, efficiently, and in compliance with standards.

You also benefit from our technical expertise during ongoing operation: Regular maintenance and inspections in accordance with the German Machinery Regulations (AMVO) and the respective manufacturer’s specifications extend the service life of your machine and ensure its value retention. With customized maintenance packages, you not only save costs but also time – because we proactively remind you of upcoming service intervals.

Should a problem arise, quick assistance is guaranteed: Our technicians will come directly to you with a wide range of spare parts and resolve many problems on the first visit. In many cases, even a phone call is enough – our experienced service back office will support you via email at orwak-service@interzero.at or by phone with troubleshooting.

You’ll also receive excellent support beyond this: We reliably supply you with consumables such as binding tape and garbage bags. And our in-house service team is available to answer any questions you may have about your machine.

By the way: Upon request, we also take care of maintenance and repairs for machines not purchased through Interzero. Simply contact us – we’ll be happy to see how we can support you. Discover machine service now

Would you like to learn more about our service offerings or put together a customized maintenance package?

We are happy to be there for you personally!

Latest News

Focus discussion on sustainable packaging solutions:

Cooperation with Leitbetriebe Austria

Textile recycling in transition:

Why companies should act now

Interzero Webinars & Events:

Stay up to date!

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Well packaged for the future: PPWR in focus at Interzero

Strong impulses and clear positions

In his welcoming speech, Interzero Managing Director Thomas Glatz emphasized: “Every day counts – our goal must be to keep resources in circulation and drastically reduce consumption.”

With a well-founded keynote speech, our packaging engineer Jonathan Scheck provided the foundation for the technical discussion: “The PPWR is part of the European Green Deal and will gradually become the mandatory basis for recyclable, resource-saving packaging solutions throughout the EU. Recyclability, recycled material requirements, single-use bans, and harmonized labeling requirements are among the core elements of the new regulation .”

The topic of eco-fee modulation – i.e. the adjustment of license fees to recyclability – was also a central part of the presentation.

Practical examples and voices from the business world

Participating companies such as Coca-Cola HBC Austria, Adamol, Brantner, Würth, and Austrian Post reported on their own packaging optimization measures and emphasized the need for joint solutions, particularly to support small and medium-sized enterprises. There was agreement that sustainable packaging can only succeed through close cooperation between business, politics, and consumers.

Interzero: The partner at your side

As a leading provider of circular economy solutions, we provide our customers with comprehensive support in implementing the PPWR: from licensing and material analyses to specific packaging optimization. Our experts work on customized solutions to prepare companies for the upcoming requirements – data-driven, reliable, and Europe-wide.

Would you like to know what the PPWR specifically means for your company?

You can find more information on our detailed page “The EU Packaging Regulation PPWR” or contact us for your personal consultation!

Insights and photos of the event can be found here:

Deepen your knowledge

Whitepaper for download:

Interzero supports companies in the transformation necessary to implement the obligations of the PPWR in a timely manner. Get detailed information and recommendations for action on the PPWR and EPR in our white paper.

Please fill out the form to access the white paper:

Do you have questions about the white paper or the topic of “PPWR”? Do you need help with your specific problem?

Write to us at the email address below and we will be happy to help you!

Latest News

Machine service at Interzero:

Well looked after all round

Textile recycling in transition:

Why companies should act now

Interzero Webinars & Events:

Stay up to date!

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

New Battery Regulation: What companies need to know now

With the new EU Battery Regulation, Europe is entering a new era of sustainable product responsibility. Its core is a comprehensive life cycle approach that, for the first time, regulates all phases of battery production – from raw material extraction through production and use to collection, reuse, and recycling.

The regulation not only replaces the previous EU Directive 2006/66/EC, but also raises the requirements to a new level – with concrete obligations, labeling requirements, and reporting obligations. Learn what applies in Austria and what you need to pay attention to here.

The most important changes to the new EU Battery Regulation at a glance:

- New battery categories: In the future, there will be five battery categories. In addition to device, automotive, and industrial batteries, batteries for light transport (LV) and batteries for electric vehicles (EV) will be introduced.

- Holistic life cycle approach : Companies bear responsibility across the entire life cycle – from production to disposal.

- CO2 footprint : Maximum CO₂ footprint values will apply in the future for industrial, LV and electric vehicle batteries.

- Recycled content : From 2031, minimum recycled content will be required for industrial, LV and electric vehicle batteries, e.g., 16% cobalt and 6% lithium.

- Performance standards: From 2027, new minimum requirements for durability, capacity and internal resistance will apply to some battery categories.

- Easy removal and replaceability: From February 18, 2027, portable batteries must be easily removed and replaced by the end user (except in exceptional cases).

- Labeling requirements : From August 18, 2026, batteries must be labeled in detail. From 2027, a QR code with a digital battery passport will follow for larger LV and industrial batteries (> 2 kWh) and electric vehicle batteries.

- Due diligence obligations : From 2025, companies with a turnover of more than €40 million must consider the impacts of the procurement, processing and trade of raw materials required for battery production.

From 2026 – new reporting obligations under the EU Battery Regulation

The new regulation also brings extensive changes to the Austrian reporting system. Existing categories are being revised and new categories are being introduced. The final version of the reporting categories is currently being coordinated:

- Monthly reporter : from 01/2026

- Quarterly reporter : from Q1/2026

- Annual reporter : Report for the year 2026 Flat rate reporters are also affected – an adjustment of the flat rates is currently being prepared.

Schedule – Here is an overview of the most important deadlines:

- 18.08.2024: Obligation to carry out conformity assessment

- 18.08.2025: Due diligence obligations & EPR mandatory

- 18.08.2026: Labeling requirements come into force

- 18.02.2027: QR code & battery passport mandatory

- 18.08.2027: Minimum standards for battery performance

- 18.08.2028: Declaration of recycled content required

- 18.08.2031: Minimum recycled material quotas mandatory

- 18.08.2036: Increase in recycled content

Which battery categories are affected by the new EU Battery Regulation?

- Portable batteries (under 5 kg, neither for LV, starter or electric vehicle batteries)

- Starter batteries (e.g. for cars)

- Industrial batteries (over 5 kg, not EV or LV)

- NEW: LV batteries (for light electric vehicles under 25 kg)

- NEW: Electric vehicle batteries (> 25 kg for hybrid and electric vehicles)

Our service for your company:

Our expertise lies in the rapid, straightforward, and practical implementation of the new requirements. Batteries must be collected, taken back, and recycled after they are placed on the market. Transfer your obligations for the take-back and recycling of device, vehicle, or industrial batteries in Austria to Interzero Austria – reliably, legally compliant, and efficiently.

Your advantages with us:

- our many years of experience in product responsibility,

- individual support from our experts,

- clear support in converting your reporting systems,

- sound advice on reporting, labeling and take-back obligations.

Our solutions for secure compliance of your batteries:

All details about the commitment and redemption at Interzero can be found here: Battery licensing

Also relevant for Austria:

- National implementation of the EU regulation is no longer necessary – it applies directly .

- Austria is responsible for supplementary regulations, such as the Battery Accompanying Act , which is currently still being coordinated and regulates points regarding the collection and return of used batteries in detail.

- Documentation requirements are increasing significantly – for example through QR codes and battery passports.

- The requirements for collection and recycling are increasing – including stricter documentation requirements .

Would you like to know which specific steps are necessary for your company?

Take advantage of our free webinars or get individual advice.

Latest News

A concept for your waste:

Save time, money and space

Your holistic environmental service provider:

Everything from a single source

Interzero & Bienenfink:

Together for biodiversity

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

A concept for your waste: save time, money and space

In many Austrian companies – whether SMEs or large corporations – waste management has evolved over the years rather than being strategically planned: skips, separation systems, and collection intervals have been adjusted selectively, often out of necessity. The result: high costs, a lack of space, complex coordination – and a constant stream of new emergency solutions. However, a well-thought-out waste management concept can achieve significant savings .

Interzero as a solution partner for your waste management concept

As a holistic environmental services provider, we understand these challenges firsthand. Last year, we developed over 500 customized solutions for our clients and restructured and successfully implemented numerous waste management concepts. Our goal is always the same: less effort, lower costs, and greater efficiency – all without compromising on environmental and waste disposal standards.

Two practical examples:

- Small business in Carinthia : By integrating a small press, annual transport costs were reduced by over €8,000 . The investment paid for itself in the first year. Additionally, valuable storage space was freed up, and coordination costs were significantly reduced due to fewer pickups.

- Large company with multiple locations : For an industrial customer with six locations in Austria, Interzero coordinated 332 collections per year. As a central point (“one face to the customer”) , we relieved the customer’s workload by communicating with 30 contacts, consolidating processes, and significantly reducing coordination effort. The result: noticeable cost savings , less operational complexity, and consistently more efficient waste management.

Our promise:

Whether you’re an SME or a large company, we develop customized concepts for your business. Whether with or without investment, you’ll benefit from tailor-made solutions that save space, money, and time .

Take the first step towards optimizing your waste processes.

The first three companies that contact us will receive a free on-site inspection by our experts – including a potential analysis and concrete implementation suggestions.

Digital. Transparent. Efficient: Our waste management platform.

Do you want to go one step further?

Our new Waste Management Platform digitizes your waste processes – from commissioning to collection to reporting. You benefit from a central contact, a single invoice, complete transparency across your waste streams, and optimized processes that significantly reduce your administrative burden.

Latest News

New battery regulation:

What companies need to know now

Your holistic environmental service provider:

Everything from a single source

Interzero & Bienenfink:

Together for biodiversity

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Everything from a single source - your holistic environmental service provider

With around 2,000 employees and annual sales of nearly one billion euros, Interzero operates throughout Europe and supports more than 50,000 customers on their path to greater sustainability. Our strength lies not only in our size, but also in our commitment to creating real added value through networked solutions. In 2023 alone, our activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary resources, according to Fraunhofer UMSICHT. As recipients of the 2024 German Sustainability Award, we see it as our mission to deliver sustainable solutions – including in Austria.

Interzero stands for more than packaging licensing

Because here in Germany, too, we stand for more than just packaging licensing: Our services range from customized waste management concepts , efficient machine solutions , and packaging design including recyclability assessments to digital reporting , consulting , and international compliance management . Together with our customers, we develop tailored strategies to optimize environmental performance – measurable, holistic, and economically viable.

Your advantage with Interzero:

Many companies still rely on standalone solutions. This often leads to interface problems, duplicate coordination efforts, and inefficient processes. This is precisely where we come in: Our services integrate seamlessly . You benefit from a central contact, consistent support, and intelligently networked processes – for greater transparency, faster implementation, and lower costs.

It’s worth looking beyond your own horizons:

If you currently only use one of our services, discover the full potential of our integrated offerings now. Whether licensing, operational disposal, reporting, or consulting – with Interzero, you get everything from a single source. This not only reduces complexity but also measurably increases your sustainability performance.

Get to know our entire offering and get your personal company presentation!

👉 Write to us – we look forward to hearing from you!

Latest News

A concept for your waste:

Save time, money and space

New battery regulation:

What companies need to know

Interzero & Bienenfink:

Together for biodiversity

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Interzero launches digital waste management platform for efficient waste management in companies

With its new Waste Management Platform, Interzero is digitizing operational waste management and significantly reducing administrative burdens for companies. The platform enables centralized control of all waste management processes across multiple locations, optimizes cost control, and saves valuable working time. Interested companies can test the Waste Management Platform free of charge and without obligation.

Vienna, April 28, 2025 – Waste management is a significant burden for many companies: Waste streams must be documented, legal regulations must be complied with, and contracts with various service providers must be coordinated. Interzero’s new digital Waste Management Platform now offers companies a simple, transparent, and efficient solution to centralize and optimize these processes.

Cost reduction through optimized waste management processes

To meet the needs of companies in different industries, Interzero has developed the new platform in close cooperation with its customers “Our Waste Management Platform is an intuitive and powerful solution for digitally managing and optimizing the entire waste management process. This helps companies operate more efficiently and reduce their costs.” , says Thomas Glatz, Managing Director at Interzero Austria.

Individually customizable reports and dashboards provide a constant overview of waste volumes and costs incurred. Based on this data, savings potential can be identified and, for example, disposal intervals can be adjusted. Companies with a complex structure – for example, with multiple locations – benefit particularly. This is because the Waste Management Platform can reduce administrative workload by up to ten working days per year. This means companies only have one contact person and receive a single invoice. “For companies with more than two locations, this reduces complexity enormously. This frees up valuable resources that they can invest in their core business,” explains Glatz.

The most important advantages of the Waste Management Platform at a glance

- Central control : Locations, waste streams and service providers are clearly managed on one platform.

- Time and cost savings : Projected time savings of up to 10 working days per year through reduced administrative effort.

- Individual evaluations : Recording and analysis of all relevant waste data in real time.

- Performance analysis : Detailed controlling and reporting functions for greater transparency and cost control.

- Ease of use : Easy operation at the touch of a button – available anytime and on all mobile devices.

Companies interested in the Waste Management Platform can test it free of charge and without obligation.

Further information on Interzero’s new Waste Management Platform can be found at: https://interzero.at/leistungen/waste-management/waste-management-plattform/

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 80,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

EUDR: What companies need to know about the new EU deforestation regulation

Global deforestation is one of the greatest threats to our climate, biodiversity, and the livelihoods of millions of people. To address this challenge, the European Union adopted the new EU Regulation to curb trade in products linked to deforestation and forest degradation in May 2023. This regulation, also known as the EU Deforestation Regulation (EUDR) , requires companies to demonstrate deforestation-free supply chains starting December 30, 2025.

What is the EUDR Regulation?

The aim of the EUDR is to prevent the import of products that contribute to global deforestation into the EU market. In particular, the regulation affects raw materials such as palm oil, soy, coffee, cocoa, beef (meat), rubber, and wood , as well as processed products containing these raw materials, such as chocolate, paper, or furniture. The EUDR requires companies to provide evidence that all affected products have not caused deforestation and comply with the legal requirements of the country of origin.

Why was the EUDR created?

The EU contributes significantly to global deforestation, as many agricultural products in the Union are sourced from deforested land. Forests are not only an important carbon sink and habitat for numerous animal species, but they also provide the livelihoods of many indigenous peoples. The EUDR aims to help stop the conversion of forests into agricultural land and reduce pressure on natural resources. Another important aspect is protecting biodiversity and preventing illegal evictions of communities and indigenous peoples.

Which products are affected in the EUDR?

The EUDR applies to various commodities and their derivatives, including:

- Palm oil

- soy

- Coffee

- cocoa

- Beef (but not milk)

- rubber

- Wood products (including paper, furniture, charcoal)

These products must either be deforestation-free or provide a detailed due diligence statement proving that no deforestation was involved in the production of the product. It doesn’t matter whether the products were manufactured in the EU or elsewhere—the EUDR applies worldwide.

The requirements for companies

Companies must demonstrate that their products meet the following conditions:

- Deforestation-free : Raw materials must not come from areas where deforestation occurred after December 31, 2020. Furthermore, harvesting must have been carried out in a manner that does not harm the forest ecosystem.

- Compliance with the laws of the producing country : In addition to EU requirements, producers must comply with the national environmental protection laws, labor rights and human rights regulations of the producing country.

- Due Diligence Declaration : A key obligation for companies is the preparation and submission of a due diligence declaration. In this declaration, companies must demonstrate that they have collected all relevant information regarding the origin and production methods of their products and that the risks related to deforestation and forest degradation have been assessed.

How does due diligence work?

Companies that place raw materials or products on the EU market must ensure that their products are deforestation-free through a three-step due diligence process:

- Information collection : Companies must collect information about their products, such as origin, quantity, and production methods. This includes using geolocation data to trace the origin of raw materials.

- Risk assessment : Based on the collected data, companies must conduct a risk assessment. This assessment considers whether the product originates from a country with a high risk of deforestation. Products from high-risk countries are subject to stricter requirements, requiring more detailed analysis and additional risk mitigation measures.

- Risk mitigation : If a company identifies a risk of deforestation, it must take measures to mitigate that risk. This can be done by switching to more sustainable raw material sources or by implementing additional controls on suppliers.

When does the EUDR Regulation come into force?

The EUDR will enter into force in stages :

- From 30 December 2025 : The regulation applies to large and medium-sized enterprises.

- From 30 June 2026 : Small and micro-enterprises will then also have to meet the requirements of the EUDR.

This phased approach is intended to ensure that companies have sufficient time to prepare for the new regulations. Companies must submit their due diligence declarations and all relevant documentation via the EU digital information system TRACES .

Challenges and criticism

Although the EUDR is a significant step toward protecting global forests, it also presents challenges and challenges. Some companies fear that the additional documentation requirements and the associated bureaucracy will represent a significant burden. Small businesses, in particular, face the challenge of implementing the extensive requirements without the necessary infrastructure.

There are also uncertainties about how exactly the various requirements will be implemented and how the regulation will affect companies’ procurement costs. It remains to be seen how the regulation will affect international trade, especially if companies in less regulated countries could rely on less stringent regulations.

What does this mean for companies?

Companies must prepare for the new regulations by making their supply chains transparent and ensuring that all relevant data on the origin and production of their products is available. To meet the requirements, companies should take early steps to audit their suppliers and document their due diligence obligations.

The EUDR ensures that companies operate more sustainably in the long term and assume responsibility for their supply chains. Those who adapt in a timely manner can not only ensure compliance with the new requirements but also make an active contribution to environmental protection.

Conclusion

The EU Deforestation Regulation (EUDR) is a crucial step in combating global deforestation and presents companies with new challenges. Starting in 2025, companies will not only be required to bring deforestation-free products to the EU market, but will also be required to provide comprehensive evidence of the origin and sustainability of their products. This regulation will help protect forests and their biodiversity worldwide and combat global climate change.

Companies that prepare early for the requirements of the EUDR have a clear competitive advantage when it comes to implementing sustainable supply chains.

Do you have questions about the EUDR Regulation?

If you have general questions about the EUDR Regulation or would like to know what it means specifically for your company, please feel free to contact our experts! We are here for you!

About Interzero:

Interzero is one of the leading service providers for closing product, material, and logistics cycles, as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports over 50,000 customers across Europe in the responsible handling of recyclable materials, helping them improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros. According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the recipient of the 2024 German Sustainability Award and the associated special prize in the transformation field of “Resources.” Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “