Optimized licensing: Use our online EPR portal

At Interzero, we are constantly working to make our services even better for you and we are constantly developing our customer portal . Our goal is to offer our customers a central platform for everything related to EPR . A central portal that makes their processes related to license management, such as quantity reports, document management and ordering packaging, waste electrical equipment and battery license contracts, as simple as possible. With a view to the coming 2025 financial year, you can make your licensing process simpler, faster and more transparent . From mid-December 2024, you can submit your annual financial statement report for 2024 and we will ensure that you continue to meet all legal requirements. Our portal helps you keep track of everything and make the process stress-free, including meeting your reporting deadlines.

Your advantages with our EPR portal for central license management at a glance:

- Simplicity: Save your product groups as favorites and save valuable time on future notifications.

- Flexibility: Report your packaging quantities in tons or kilograms and download reports directly as PDF or Excel.

- Efficiency: Copy previous messages with just one click and reduce manual effort.

With this solution, we are specifically targeting Austrian companies that want to license their packaging, waste electrical equipment and batteries in a legally correct manner. Our portal offers you not only efficiency, but also transparency by allowing you to view your data at any time and in one place. In this way, we are laying the foundation for a legally compliant and sustainable EPR solution in Austria.

Your opinion counts!

We would like to continue to optimize our portal and look forward to your feedback. Your experiences will help us to tailor the platform even better to your needs. Please let us know your suggestions for improvement. Click here to tell us your opinion!

EPR expertise: Are you already legally compliant?

Use our new online portal and simplify your licensing in Austria. Get started now and start 2025 with legal certainty.

Latest news:

Interzero Circular Consulting

Tailor-made solutions for your compliance

EPR in Europe:

Authorization for Austria and Neighboring Countries

Circular Economy Exchange 3.0:

Expert knowledge and invitation to the event

About Interzero:

Interzero is one of the leading service providers around the closure of product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports more than 50,000 customers across Europe in the responsible use of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources.

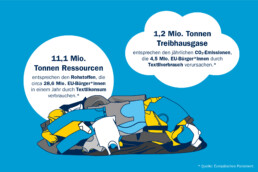

With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases compared to primary production and over 11.1 million tons of primary raw materials in 2023 alone. As a pioneer of the circular economy, Interzero is the winner of the German Sustainability Award 2024 and the associated special prize in the transformation field of “resources”. Further information can be found at www.interzero.at.

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

4% increase in collections in the first half of the year throughout Austria

Since the standardization of the collection of lightweight and metal packaging, the amount collected in Austria has been increasing continuously. In the first half of 2024, Interzero recorded a nationwide increase of 4% compared to the previous year , with the strongest increases in Vienna and Carinthia. At the beginning of 2023, the collection of lightweight packaging was standardized in Austria: Now, in addition to plastic bottles, cups, bowls and other plastic and metal packaging are collected in the yellow bag or yellow bin. The current figures from Interzero show an increase of 4% for the first half of 2024 compared to 2023. Vienna recorded the largest increase with 10% , followed by Carinthia with 8% .

“Urban areas are usually below the national average when it comes to collection. Thanks to standardization, cities are now catching up significantly ,” explains Thomas Glatz , Managing Director of Interzero Austria.

New EU directives as the next step

In the future, the collection and recycling of packaging will also be promoted by the new EU directive Packaging and Packaging Waste Regulation (PPWR) . The regulation aims to make packaging more sustainable and recyclable by 2030. With the Made4Circle service, Interzero supports companies in the implementation of recyclable packaging.

Read more about the collection increase in Austria here: Carinthians collected more in the yellow bag – kaernten.ORF.at

You can find more detailed information in our press release: Yellow bag: 4% collection increase

Latest news:

resources SAVED by recycling

Recycling as the Key to Resource and Climate Protection

Interzero on packaging day:

Presentation of innovative recycling process

Interzero Leadership Award:

award for our team

About Interzero:

Interzero is one of the leading service providers around the closure of product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports more than 50,000 customers across Europe in the responsible use of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources.

With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases compared to primary production and over 11.1 million tons of primary raw materials in 2023 alone. As a pioneer of the circular economy, Interzero is the winner of the German Sustainability Award 2024 and the associated special prize in the transformation field of “resources”. Further information can be found at www.interzero.at.

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

resources SAVED by recycling: Recycling as the key to resource and climate protection

Recycling plays a central role in conserving resources and protecting the climate. Every year, Interzero conducts a comprehensive life cycle assessment together with the Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT . This clearly shows how recycling reduces the consumption of raw materials and greenhouse gas emissions. In this way, we are making an important contribution to promoting the circular economy and achieving global climate goals . “resources SAVED by recycling” serves as the key to resource and climate protection. In 2023, Interzero saved more than 11.1 million tons of primary raw materials by recycling around 2.5 million tons of recyclable materials in Germany, Austria, Poland, Italy and Slovenia . This amount corresponds to the raw materials that around 28.6 million EU citizens consume in one year through their textile consumption. In addition, these measures avoided around 1.2 million tons of greenhouse gas emissions . This corresponds to the annual CO2 emissions that 4.5 million EU citizens would cause through textile consumption. Our partnership with the renowned Fraunhofer UMSICHT makes it possible to underpin the ecological benefits of recycling with valid data. These figures prove that recycling not only conserves resources, but also represents significant added value for climate protection . The results of the study help to further advance the transformation to a circular economy and support companies in achieving their sustainability goals.

Would you like to know more about the results of the “resources SAVED by recycling” study?

Similar article on this topic: Interzero publishes study resources SAVED by recycling 2023

Latest news:

Interzero on packaging day:

Presentation of innovative recycling process

Collective plus at Interzero:

4% increase in collections in the first half of 2024

Interzero Leadership Award:

award for our team

About Interzero:

Interzero is one of the leading service providers around the closure of product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports more than 50,000 customers across Europe in the responsible use of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources.

With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases compared to primary production and over 11.1 million tons of primary raw materials in 2023 alone. As a pioneer of the circular economy, Interzero is the winner of the German Sustainability Award 2024 and the associated special prize in the transformation field of “resources”. Further information can be found at www.interzero.at.

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Yellow Bag: 4% increase in collection in the first half of 2024 throughout Austria

The standardization of lightweight packaging collection has ensured a steady increase in the amount of lightweight and metal packaging collected in Austria since its introduction. After a nationwide collection increase of 6% in the previous year, the circular economy service provider Interzero recorded an increase of around 4% in the first half of 2024. The largest increase was in Vienna with 10%, followed by Carinthia with 8%.

Vienna, October 28, 2024. Since the beginning of 2023, in addition to plastic bottles and beverage cartons, cups, bowls, foils and other plastic packaging as well as metal packaging have been collected in the yellow bag or yellow bin throughout Austria. Current figures from the circular economy service provider Interzero show an Austria-wide increase of 4% for the first half of 2024 compared to the first half of 2023. The largest increase in Vienna with 10%, followed by Carinthia with 8%.

The largest increase in collections was achieved in Vienna with an increase of 10%. Behind this is Carinthia with an increase of 8%, and the largest increase there was recorded in Klagenfurt with also 10%. ”

In cities in particular, the amount of lightweight and metal packaging collected is slightly below the national average, even if they have been catching up since the standardization of collection. But that explains why Vienna and Klagenfurt are at the forefront of the current growth rates.” , says Thomas Glatz, Managing Director at Interzero Austria. Packaging and Packaging Waste Regulation (PPWR) as the next milestone

In the future, the recycling of packaging will also be driven forward by the European Union’s new Packaging and Packaging Waste Regulation (PPWR). This aims to improve the sustainability of packaging, reduce packaging waste and harmonize regulations in the member states. “The PPWR is an important milestone in significantly reducing the proportion of packaging that is thermally recycled. For companies, it means that by 2030 all packaging must be either reusable or recyclable. With our ‘Made4Circle’ service, we support companies in the development of recyclable packaging and cover the entire process – from analysis to implementation,” explains Thomas Glatz.

About Interzero:

Interzero is one of the leading service providers for closing product, material and logistics cycles and an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions”, the company supports over 50,000 customers across Europe in the responsible handling of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the winner of the German Sustainability Award 2024 and the associated special prize in the transformation field of “resources”. Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Interzero Leadership Award 2024: Award for our team

At our international management meeting, which took place this year in picturesque Bled, Slovenia, we had every reason to celebrate: The Interzero Leadership Award 2024 was presented and six of our Austrian colleagues received nominations for their outstanding work. The award was given in three categories:

- Getting the right things done

- Leadership

- Values first

Our nominees are among the quiet heroes of everyday life who lead with passion and commitment and make a significant contribution to Interzero’s success. We are proud that the following colleagues from Austria have been nominated for their extraordinary achievements:

- Vivienne Kovacs (Country Digital Manager) and Alberto Aglietti (Business Controller) in the “Getting the right things done” category

- Julian Hafner (Head of Recycling WEEE & BAT) in the category “Leadership”

- Anna Stifter (Finance Director), Nathalie Kirchner (Strategy & Organization) and Thomas Glatz (Managing Director) in the category “Values first”

These nominations are an expression of appreciation for the tireless commitment and excellent work of our team. Their achievements go far beyond the everyday and are an important sign of the trust that our customers can place in us. In addition to our nominees, we would also like to congratulate the international winners who won the Interzero Leadership Award 2024 in their categories:

- Piotr Kiryluk (Finance Director Interzero Poland) in the category “Getting the right things done”

- Agata Ryś (Board Member Interzero Poland) in the category “Leadership”

- Sergio Patacchini (Senior Sales Manager Interzero Italy) in the category “Values first”

Their success shows that top performance and dedication pay off. Together, we come one step closer to our goal of a world without waste every day.

Congratulations to all nominees and winners! Your work is not only proof of your exceptional skills, but also a motivation for the entire team. We are proud to have you in our company and thank you for your daily commitment.

Latest news:

resources SAVED by recycling

Recycling as the Key to Resource and Climate Protection

Collective plus at Interzero:

4% increase in collections in the first half of 2024

Interzero on packaging day:

Presentation of innovative recycling process

About Interzero:

Interzero is one of the leading service providers around the closure of product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports more than 50,000 customers across Europe in the responsible use of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources.

With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases compared to primary production and over 11.1 million tons of primary raw materials in 2023 alone. As a pioneer of the circular economy, Interzero is the winner of the German Sustainability Award 2024 and the associated special prize in the transformation field of “resources”. For more information, visit www.interzero.at.

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Interzero presents pioneering recycling process for high-density polyethylene (HDPE)

On October 10, 2024, the Austrian Packaging Day took place at FH Campus Wien, focusing on the future of the packaging industry under the motto “Sustainable, Circular and Safe Packaging: Global Trends and Local Implementation” . The event brought together representatives from all areas of the industry – from manufacturing companies, from the packaging development sector, to suppliers and research institutions. Interzero was represented with a groundbreaking contribution that underlined our role as an innovation leader in the field of plastics recycling. A highlight was the lecture by Dr.

. Manica Ulcnik-Krump, Geschäftsführerin von Interzero Plastics Innovations, in which it presented “New developments in HDPE recycling” . HDPE stands for high-density polyethylene , a plastic that is often used in products such as plastic bottles. With the Packaging and Packaging Waste Regulation (PPWR) adopted in November 2023, companies now face the challenge of incorporating a certain percentage of recycled plastic, so-called post-consumer recyclate (PCR) , into their packaging. However, the use of PCR materials is proving challenging as their complex properties often obscure performance compared to virgin materials. Interzero has responded to these challenges by developing a patented mechanical recycling process that incorporates chemical modifications to improve material properties and ensure higher quality. The process, which specifically focuses on blow molded products made from 100% recycled material from lightweight packaging (LVP) , sets a new standard. Until now, HDPE recycling was only suitable for simple applications such as extrusion. Now, however, thanks to a chemically controlled rheology modification, the material can be modified to have the same flow properties as new plastic. This opens up new possibilities for applications such as blow molding, which is crucial in the production of plastic bottles. A major advantage of this process is that it no longer requires the addition of new plastic, so-called primary plastic. This not only saves resources such as petroleum , but also significantly reduces CO2 emissions . In addition, avoiding energy-intensive sorting processes ensures additional CO2 savings. The process is continuously developed and perfected at the Interzero Competence Center for Plastics Recycling in Maribor. In addition to reducing CO2 emissions, this innovative recycling process offers the packaging industry an economically viable way to source high-quality raw materials from recycled plastic without compromising on material quality. These sustainable solutions help meet the European Union’s ambitious climate targets and the PPWR requirements.

More on the topic of HDPE for bottle production and innovative developments?

Read more about this topic in our article: HDPE for bottle production made from 100% LVP for the first time – Interzero receives patent for more sustainable process for plastic recycling – Interzero – Your strong environmental service provider

Our brochure gives you a comprehensive insight into the research and services of Interzero’s own competence center.

Latest news:

resources SAVED by recycling

Recycling as the Key to Resource and Climate Protection

Collective plus at Interzero:

4% increase in collections in the first half of 2024

Interzero Leadership Award:

award for our team

About Interzero:

Interzero is one of the leading service providers around the closure of product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports more than 50,000 customers across Europe in the responsible use of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources.

With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases compared to primary production and over 11.1 million tons of primary raw materials in 2023 alone. As a pioneer of the circular economy, Interzero is the winner of the German Sustainability Award 2024 and the associated special prize in the transformation field of “resources”. Further information can be found at www.interzero.at.

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Interzero publishes study "resources SAVED by recycling 2023"

+++ Study by Fraunhofer UMSICHT proves positive environmental effects of recycling

+++ Interzero will save around 1.2 million tonnes of greenhouse gases and 11.1 million tonnes of primary resources in 2023

+++ Europe’s leading circular economy service provider is driving textile recycling forward: Enormous potential for climate and resource protection

Vienna, October 8, 2024. More recycling, less wasted resources: The recycling of raw materials is an effective lever to counteract the exploitation of our planet and prevent a further escalation of the climate crisis. The study “resources SAVED by recycling” published today proves this with clear facts: In 2023, Europe’s leading circular economy service provider Interzero avoided a total of 1.2 million tons of greenhouse gas emissions by recycling around 2.5 million tons of recyclable materials. This corresponds to the annual CO2 emissions caused by 4.5 million EU citizens through their textile consumption alone. At the same time, Interzero and its customers were able to save over 11.1 million tons of primary resources . This amount is comparable to the raw material consumption caused by around 28.6 million people in the EU in one year through their textile consumption.* “ Looking at textiles as a recyclable material, it becomes clear what enormous ecological potential there is in recycling – and why it is urgently necessary to drive forward the circular transformation of the economy at all levels ,” says Dr. Axel Schweitzer, Chairman and shareholder of Interzero. “ This is particularly true for recyclable materials that are not yet consistently recycled today .” Unlike packaging recycling, for example, textile recycling is still in its infancy: around 92 million tonnes of textiles are thrown away every year worldwide. So far, however, only one percent of the huge material flow goes into fibre-to-fibre recycling and thus back into the production cycle. “ Together with the industry, we want to close the textile cycle and use our experience as an established system service provider to develop a holistic concept for take-back, sorting and recycling,” says Dr. Axel Schweitzer . “ In this way, we are easing the burden on the environment and supporting companies in becoming circular, i.e. future-proof and competitive .” Time is of the essence, as new EU regulations such as the separate collection requirement from 2025 or the planned producer responsibility for textiles (EPR), as well as the Austrian federal government’s circular economy strategy , are increasing the pressure to act .

“With our comprehensive services, we already enable companies to keep a wide variety of recyclable materials in the cycle and thus meet the requirements of regulations – such as the PPWR. In the future, we will also make this possible for textiles “, says Thomas Glatz , Managing Director at Interzero in Austria . Inform, educate and provide solid arguments for the circular transformation of the economy : With this goal in mind, Interzero has been having the environmental impacts of recycling independently scientifically reviewed for over 15 years. The annual life cycle assessment by the Institute for Environmental, Safety and Energy Technology Fraunhofer UMSICHT demonstrates the sustainable impact of Interzero’s work – and supports the circular economy service provider’s customers in transparent sustainability communication. For its holistic commitment, Interzero was awarded the German Sustainability Award 2024 in the “Waste Disposal and Recycling Industry” category and also the special prize in the resources transformation field.

*The conversion examples are based on figures from the European Parliament.

About Interzero:

Interzero is one of the leading service providers for closing product, material and logistics cycles and an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions”, the company supports over 50,000 customers across Europe in the responsible handling of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved 1.2 million tons of greenhouse gases and 11.1 million tons of primary raw materials compared to primary production in 2023 alone. As a pioneer of the circular economy, Interzero is the winner of the German Sustainability Award 2024 and the associated special prize in the transformation field of “resources”. Further information can be found at www.interzero.at .

Find out more in our current brochure on ” resources SAVED by recycling “

Contact

You still have questions? We are here for you!

Interzero Austria at the World Cleanup Day: Together for a clean environment

Interzero Austria gets to work: Together for a clean future

On September 20th, we at Interzero Austria took part in World Cleanup Day for the first time. Young colleagues in particular, who care about protecting our environment, set out with a clear goal: to set an example for environmental protection and to further advance our vision of a “world without waste”.

Together for Environmental Protection

Equipped with gloves and garbage bags, we as a team not only collected garbage, but also took on our responsibility for future generations. In cooperation with Green Heroes Austria, we want to continue to actively make a difference – because environmental protection concerns us all!

Thanks and Outlook

Special thanks go to our entire team and all the dedicated volunteers who are helping out everywhere. Even small steps take us further, and we remain motivated to take responsibility – for nature and future generations. Quote from Mag. Thomas Glatz , Managing Director of Interzero Austria: “World Cleanup Day is an important part of our mission to continuously postpone Earth Overshoot Day. Especially after the severe storms of the last few days, our commitment to a clean environment is more important than ever. Together we can achieve a lot – every small contribution counts.”

Latest news:

Innovative machine solutions from Interzero: Dealing with recyclable materials and waste more efficiently

About Interzero:

Interzero is one of the leading service providers around the closure of product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports more than 50,000 customers across Europe in the responsible use of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved one million tons of greenhouse gases compared to primary production and over 8.7 million tons of primary raw materials in 2022 alone. For more information, visit www.interzero.at.

Find out more in our latest brochure on “resources SAVED by recycling”.

Contact

You still have questions? We are here for you!

New laboratory for plastics innovations opened in Maribor

On September 18, 2024, the Interzero Plastics Innovations doo competence center celebrated the opening of its state-of-the-art laboratory and office space in the Lenart Industrial Zone, Maribor, Slovenia. This internationally accredited research facility specializes in the development of innovative recycled plastics and continues to advance research into sustainable plastics solutions. The opening ceremony was attended by high-ranking guests, including the President of the Republic of Slovenia, Dr. Nataša Pirc Musar , and Dr. Axel Schweitzer , Chairman of the Board of Interzero. Both emphasized the enormous importance of innovations in the field of plastics recycling to realize the vision of a circular economy.

At the event , Thomas Glatz , Managing Director of Interzero Austria, also praised the team’s outstanding work: “Dr. Manica Ulcnik-Krump and her team have accomplished something great and built a ‘state of the art’ laboratory in a very short time. Around 40 new recycled material recipes are created here every year and hundreds of packages are tested for their recyclability as part of our ‘Made4Recycling’ service. We are working hard on innovations to bring us closer to our vision of ‘a world without waste’.”

The laboratory, which is internationally accredited according to ISO/IEC 17025:2017, carries out a wide range of analytical methods and supports companies in making their production processes more sustainable. With tailor-made solutions, the competence center helps to produce high-quality recycled plastics that can replace primary raw materials – a decisive step towards a more sustainable future . With the opening of these new premises, Interzero’s innovative power is further strengthened in order to advance the circular economy in Europe.

Latest news:

Innovative machine solutions from Interzero: Dealing with recyclable materials and waste more efficiently

“Glass Loop Project”: Transforming waste into new products

Interzero Austria at the World Cleanup Day: Together for a clean environment

About Interzero:

Find out more in our current brochure on “resources SAVED by recycling”

Contact

You still have questions? We are here for you!

“Glass Loop Project”: Transforming waste into new products

Did you know that we make rubber boots from production waste from car windows?

Interzero’s “Glass Loop Project” shows how circular economy works in practice. Instead of simply disposing of the leftovers from the production of car windows, we recover PVB film residues and recycle them into granulate . This granulate then serves as the starting material for the production of rubber boots – a perfect example of how we convert waste into valuable resources and thus close the loop. This project is part of our comprehensive Integrated Environmental Solutions (IES) approach. With IES, Interzero offers companies tailor-made solutions to minimize their waste streams, use resources more efficiently and at the same time achieve economic benefits. Through the innovative use of recycling technologies, we support companies not only in reducing waste but also in tapping into new value creation potential .

More than just waste management

Interzero’s IES goes far beyond traditional approaches to waste management. It is a holistic concept that helps companies achieve their sustainability goals while increasing operational efficiency. The transformation of production waste into recyclable materials – as in the “Glass Loop Project” – illustrates how waste can not only be avoided, but can also be turned into an economic advantage .

Future-oriented solutions for sustainable success

Consumer preferences are changing and sustainability is increasingly becoming a key factor in purchasing decisions. Companies that focus on circular economy and sustainable business models not only secure environmental benefits but also a clear competitive advantage .

Sustainability with measurable added value

Interzero’s approach to the circular economy shows that environmental protection and economic success can go hand in hand. With projects like the Glass Loop, we create innovative solutions that not only protect the environment but also bring economic benefits – be it by reducing costs or opening up new sources of income through the recycling of waste. Watch our video to learn how the “Glass Loop Project” works and how IES can help your company turn waste into valuable resources. Shape a sustainable future with us!

Latest news:

Innovative machine solutions from Interzero: Dealing with recyclable materials and waste more efficiently

Interzero Austria at the World Cleanup Day: Together for a clean environment

About Interzero:

Interzero is one of the leading service providers around the closure of product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions,” the company supports more than 50,000 customers across Europe in the responsible use of recyclable materials, helping them to improve their own sustainability performance and conserve primary resources. With around 2,000 employees, the company generates sales of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities saved one million tons of greenhouse gases compared to primary production and over 8.7 million tons of primary raw materials in 2022 alone. For more information, visit www.interzero.at.

Find out more in our latest brochure on “resources SAVED by recycling”.